rockwell hardness test principle|rockwell hardness testing method : dealer The Rockwell hardness test is the industry standard measuring system used to determine how resistant a material is to another object. Hardness is defined as a material’s resistance to permanent indentation. .

Boneco promo codes, coupons & deals, February 2024. Save BIG w/ (13) Boneco verified coupon codes & storewide coupon codes. Shoppers saved an average of $20.00 w/ Boneco discount codes, 25% off vouchers, free shipping deals. Boneco military & senior discounts, student discounts, reseller codes & Boneco.com Reddit codes.

{plog:ftitle_list}

21/02/2023 20h37 Atualizado há um ano. Vídeo mostra dupla matando seis pessoas em bar em MT. Um vídeo registrado por um câmera de segurança mostra o momento em que dois homens matam sete .

What is the Principle of the Rockwell Method? You can think of the Rockwell Hardness method as an impact-dependent hardness measuring method. The reason is that .Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learn more about hardness testing basics here. The Rockwell hardness test method, as .

The Rockwell principle is described as follows: An accurately shaped indenter is used to make an indent in the sample to be tested. This .The Rockwell hardness test is an empirical indentation hardness test that can provide useful information about metallic materials. This information may correlate to tensile strength, wear resistance, ductility, and other physical characteristics .Principle of Test. The Rockwell test consists of measuring the additional depth to which a carbide ball or Brale® diamond penetrator is forced by a heavy (major) load beyond the . The Rockwell hardness test is the industry standard measuring system used to determine how resistant a material is to another object. Hardness is defined as a material’s resistance to permanent indentation. .

rockwell hardness testing method

The Rockwell hardness test involves making an indentation on the test material. The indenter is either a conical diamond or a steel ball. Indenter ball diameters range from 1/16 to 1/2 inches and are chosen based .The Rockwell method is a static hardness testing method, which can be further characterised as follows: It is one of the standardised procedures (ISO 6508, ASTM E18). The process is used to test hardness in the macro range (test .The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and understand the standard completely before attempting a .

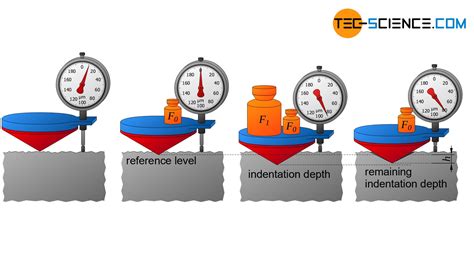

Principle of Rockwell hardness testing . The Rockwell hardness test is one of several common indentation hardness tests used today, other examples being the Brinell hardness test and Vickers hardness test. Most indentation hardness tests are a measure of the deformation that occurs when the material under test is penetrated with a specific type . In the Rockwell hardness test, the measure of the hardness is not an indentation surface but an indentation depth. Either a carbide ball or a rounded diamond cone with a tip angle of 120° and a tip radius of 0.2 mm .The Rockwell hardness test is one of several common indentation hardness tests used today, other . “Dynamic Impact” is based on the Leeb principle of hardness,developed by Dietmar Leeb in the 1970’s. A spring loaded impact body is thrust to the test surface, effecting rebound. The speed of both the initialTheory and Principle of the Rockwell Hardness Test. The Rockwell Hardness Test uses a depth-differential method to test for hardness. A predetermined minor load is applied to the test sample, and the depth measurement is taken. Then a major load is applied to the same spot, which creates a deeper indentation. The major load is then removed, and .

Brinell hardness (1) Principle. . The Rockwell hardness test is divided into various scales, each with a wide range of applications. (5) It is important to note that Rockwell hardness values obtained from different scales are not comparable. 4. . The Rockwell hardness test is based on the measurement of the depth to which an indenter is forced by a heavy (major) load beyond the depth resulting from a previously applied preliminary (minor) load. . Rockwell testing is usually perceived to be one of the simpler testing methods, and indeed in principle it can be very quick and accurate .The Rockwell hardness test is one of several common indentation hardness tests used today, other examples being the Brinell hardness test and Vickers hardness test. Most indentation hardness tests are a measure of the deformation that occurs when the material under test is penetrated with a specific type of indenter. In the case of the Rockwell hardness test, two .

ASTM E10: This standard covers Brinell hardness testing in metallic samples. ASTM E18: This standard includes the various ways that Rockwell hardness can be measured by standard methods, specifically for metallic materials. ASTM E384: This standard is for hardness testing on a micro-scale, and therefore includes the Vickers and Knoop hardness . The residual indentation size of the indenter can be measured using optical measurement methods. Among the standardized optical hardness testing methods are the Brinell hardness test (ISO 6506, ASTM E10), the Knoop hardness test (ISO 4545, ASTM E92, ASTM E384), and the Vickers hardness test (ISO 6507, ASTM E92, ASTM E384). Brinell .

What is Rockwell hardness testing? The Rockwell Hardness Test is generally a non-destructive test performed on samples when it’s necessary to determine how hard a material is. It’s generally considered easier to perform compared to other methods, like Vickers or Brinell hardness testing. Another advantage is the small area of indentation needed to carry out the .

The Rockwell hardness test is one of several common indentation hardness tests used today, other examples being the Brinell hardness test and Vickers hardness test. Most indentation hardness tests are a measure of the deformation that occurs when the material under test is penetrated with a specific type of indenter . Variants on the Rockwell hardness test procedure are used depending on the material and strength of a part. The most common Rockwell variants include: HRC – Known as “Rockwell C,” a 150 kgf load is applied via a diamond in this method. Rockwell hardness testing is a common analytical technique for evaluating the hardness of metallics and synthetic materials. . details will be shared with OpenAI and retained for 30 days in accordance with their privacy principles. Please do not ask questions that use sensitive or confidential information. Read the full Terms & Conditions .

The Rockwell hardness test is less affected by surface rough-ness compared to other methods such as the Vickers or Brinell tests. It can provide reliable hardness measurements even on . 2.3 Functional and Calculation Principle for Brinell Sample Surface Force (F) HBW = Brinell Hardness HBW = Constant x HBW = 0.102 x d 1= (Mean Indentation-Ø .Metallic materials — Rockwell hardness test — . Figure 1 — Rockwell principle diagram 5 Testing machine 5.1 Testing machine, shall be capable of applying the test forces for some or all of the Rockwell hardness scales as shown in 1Table and Table 2, performing the procedure defined in Clause 7, and .Applications of Rockwell Hardness Test. Quality Control: Commonly applied in industries that require hard materials on parts and other manufactured products. Material Selection: This tool supports the process of identifying materials that . Hardness testing is of immense importance for quality assurance in industry. Although the most widely used hardness test methods for metals—Rockwell, Brinell, and Vickers—were developed between 1900 and 1925, numerous technical innovations have been made in recent years, leading to an increase in productivity and the accuracy of hardness tests.

A Rockwell hardness tester. The Rockwell scale is a hardness scale based on indentation hardness of a material. The Rockwell test measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load). [1] There are different scales, denoted by a single letter, that use different loads or indenters. The Rockwell hardness test is the industry standard measuring system used to determine how resistant a material is to another object. Hardness is defined as a material’s resistance to permanent indentation. . It is as accurate as desk testers and complies with the basic designing principles of Rockwell hardness testing. It is used to test .This hardness testing method involved the measurement of the increment of depth of an indenter forced into the metal by a primary and a secondary load. Based on Ludwig’s principles, Stanley P. Rockwell invented the Rockwell hardness test in 1919 (Rockwell 1922). Today, it is the most widely used method to determine quantitatively the .4.3 Rockwell hardness testing at a specific location on a part may not represent the physical characteristics of the whole part . 5.1 Rockwell Hardness Test Principle— The general principle of the Rockwell indentation hardness test is illustrated in Fig. 1. The test is divided into three steps of force application and removal.

Rockwell hardness test for plastics: In this test, a load of 15 or 30 kg is applied to the surface of the plastic material for a few seconds. . 3G PRINCIPLE 3K PRINCIPLE 3M PRINCIPLE 3R 4M PRINCIPLE Avoid These Common Mistakes on a Job Interview Benefits of Kaizen Business Analysis capacity management Continual improvement Cybersecurity Cycle .Hardness Testing: Principles and Applications is an in-depth study of one of the most fundamental properties of materials and the tools and techniques that have been developed to measure it. Hardness, as defined in the first chapter, is a type of resistance to deformation, the roots of which lie in the packing density of atoms and the bonding forces that keep them in place.

3.1.7.3 portable Rockwell hardness testing machine a Rockwell hardness testing machine that is designed to be transported, carried, set up, and operated by the users, and that measures Rockwell hardness by the Rockwell indentation hardness test principle. 3.1.7.4 movable Rockwell hardness testing machine a Rockwell hardness testing machine .Basic principle and practical procedure of the Rockwell hardness test - Testing machine, test piece, conical diamond indenter - Basic principle, hardness d.

rockwell hardness tester least count

The Rockwell hardness test employs the principle of differential-depth method. During the test, the indenter of the equipment is forced to make a residual depth on the test specimen. This is called as an indent and its depth is measured. The total test force is applied in two stages to eliminate errors caused due to the roughness of the surface .

rockwell hardness test theory

rockwell hardness test calculation

lumen compression tester

Concurso 6257. 03/10/2023. 31. 42. 45. 71. 80. 2 ganhadores. R$ 17.606.849,74. Próximo prêmio. R$700.000,00. (em 04/10/2023) Análise estatística. Estatísticas. Mais atrasado. .

rockwell hardness test principle|rockwell hardness testing method